Rotowrap TT

Special features of the Rotowrap TT bale wrapping system:

Rotowrap TT is the practical and reliable machine for wrapping your waste bales. It is an economical solution for plants with a throughput of up to 15 bales per hour for bale weights of up to 850 kg.

The machine meets the highest of requirements while ensuring the efficient and exact wrapping of square and round bales during stationary operation.

A practical design, superior-quality components and the latest production processes make this bale wrapper the first choice for customers in the recycling industry who require a plant for wrapping operations in the most confined space.

In the case of the Rotowrap TT, both the rotations required for the complete wrapping of a bale are realised simultaneously (around both axes). Turning of the bale through the oscillating roller pairs on the turntable achieves a uniform, reliable and controlled rotation around the longitudinal bale axis.

Rotation of the turntable simultaneously rotates the bale around the vertical axis during this procedure. These two rotations are executed in a fixed relationship to each other. Film is evenly wrapped around the bale during this using the fixed film prestretcher, ensuring an overlapping of film layers of 55 %. This saves time during the wrapping process and achieves the best possible sealing of the bale.

- minor to medium requirements

- bale weights of up to 850 kg

- Up to 15 bales/h

- Square and round bales

- Exact and tightly sealed wrapping (55% overlapping of film layers)

- Economical film consumption

- The least expensive waste wrapping machines on the market

- Wrapping in the most confined space

Rotowrap TT - How does it work ?

This wrapper features superior-quality equipment, due to the demanding requirements of the recycling industry.

The practical film cutting and holding device and the highly efficient aluminium prestretcher optimise film consumption and minimise maintenance requirements. The oscillating roller pairs ensure that bales with the most varied dimensions are rotated accurately so that the film is applied evenly. A simple conversion of the machine also enables the wrapping of round bales with a diameter of up to 1.5 m.

The machine is either loaded manually with a forklift truck with bale forks or using an automatic loading system.

Machine operation is realised fully automatically via a computer or remote control.

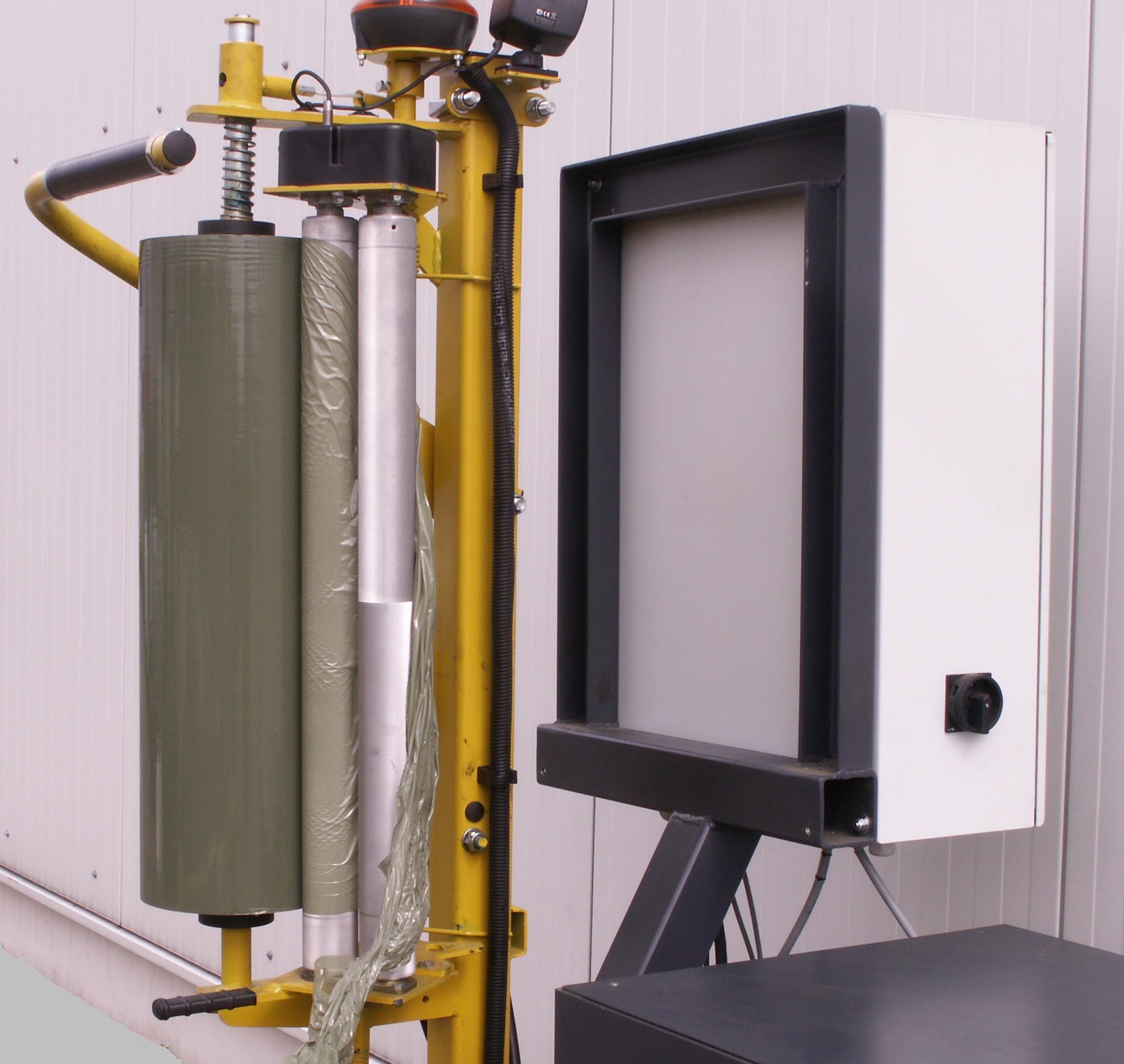

ROTOWRAP TT - Wrapping unit

Hydraulic unit:

The Rotowrap TT has an integrated hydraulic unit which is electrically powered by a 5.5 kW motor. The electric motor is automatically deactivated if the machine is stationary for a longer period, thus saving electric power and avoiding unnecessary heating of the oil.

Cutting and holding device:

The hydraulic cutting and holding device is fitted to the turntable next to the rollers. It bundles and cuts the wrapping film reliably and cleanly. During this, it automatically holds the film ready under the roughest conditions for the next bale.

Rotating turntable:

Both roller pairs can be pivoted within the frame mounted on the turntable, allowing the four rollers to adapt to the shape of the bale while the bale is rotating. This patented system is known as oscillating rollers. The rotating wrapping arm and the oscillating rollers rotate the bale in a fixed relationship to each other. This enables stretching of the wrapping film by the prestretcher unit and uniformly applied to the bale with an overlap of 55%.

The type of oscillating rollers employed depends on the material being pressed, with plastic-coated steel rollers, rubber-coated steel drums or star-shaped steel rollers being used.

Film prestretcher:

The 750mm wide film in the film prestretcher is wound up by the two prestretcher rollers and prestretched at a fixed percentage rate through the two different speeds of the prestretcher rollers. The film prestretcher can be equipped with different gearwheel pairs and is available for a prestretching range of 35 – 70 %.

The prestretcher is equipped with a rapid film roll changing system which firmly locks the film roll during wrapping and ensures rapid insertion of the new film roll.

The film is stretched by the two prestretcher rollers through the rotating action of the wrapping table, thus prestretching it over the bale.

Remote control:

Equipping the machine with a remote control enables the operator to control the wrapper from the forklift truck. The hydraulic unit oil supply is activated using the remote control automatic start. The last bale can be taken away by the forklift while the next bale is being wrapped.

Additional equipment for the Rotowrap TT

Automatic unloading system:

We have designed an unloading system to improve unloading of the machine. Up to four bales can be unloaded automatically following wrapping with the aid of this unloading system and buffered on a bale collecting belt. This gives the driver of the forklift used for unloading the machine more time for the unloading process, thus increasing the system throughput.

Automatic loading and unloading system:

We have developed a loading and unloading system so that the Rotowrap TT acts as a fully automatic machine directly downstream of the press. This system consists of a traversing crane unit fitted with a bale fork. The bale is conveyed from the ramp behind the press to the wrapper using this crane unit. The bale is transported from the wrapping table to a bale collecting belt following the wrapping process. The bale is unloaded here by the forklift truck.