Rotowrap WS

Fully automated system for bale separation, weighing and bale labeling behind a baling press.

The storage and transport of recycling goods in the form of pressed bales have increased significantly in recent years. When transported to a national and international level, these recycling goods are subject to official regulations and requirements. Therefore, it is increasingly important for storage and transport logistics to have precise information about the pressed bales and to mark the individual bales with this data so that it will be visible to everyone during transport.

Therefore, automated recording of this data during baling the bales and automated labelling of the individual bales after pressing have become necessary. PTF-Häusser has been supplying its wrapping machines with this automated weighing and labeling system for decades. Now we developed such a system for unwrapped bales located directly behind a baler and manufacture bespoken systems for our customers. As an innovative wrapping system manufacturer, we offer unrivaled detailed technical solutions for every conceivable application.

Rotowrap WS

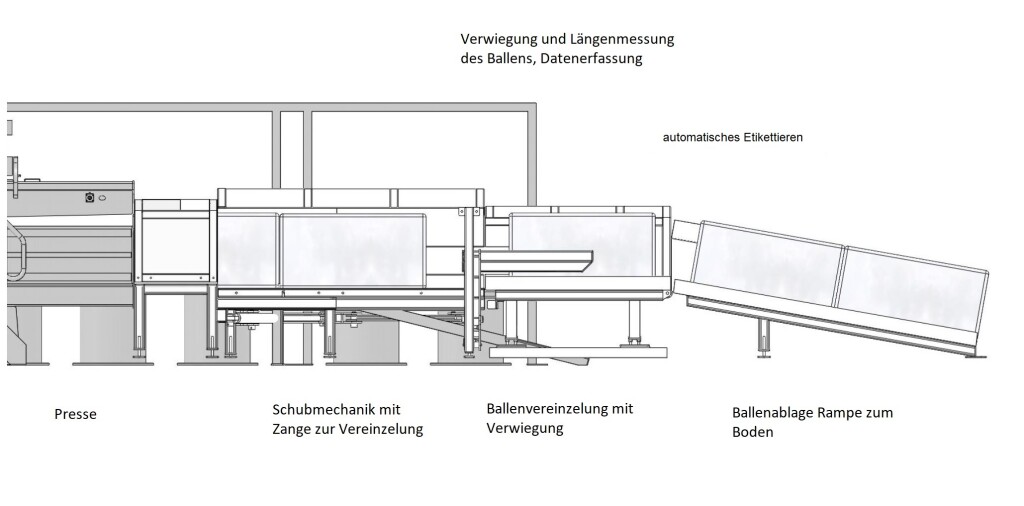

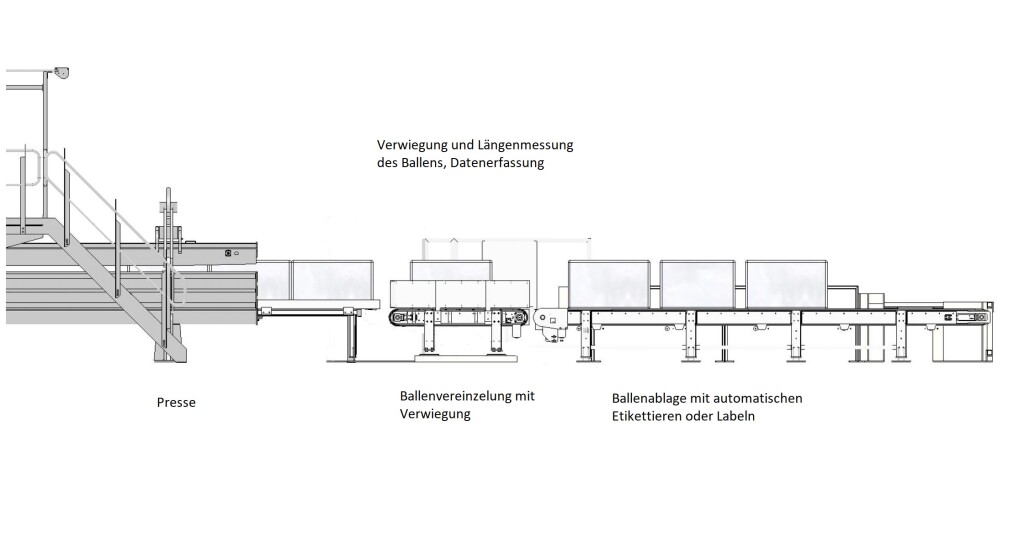

BALE SEPARATION:

The “bale separation” process step is always carried out in connection with a fully automatic baling press. The bales are separated behind the baler in the weighing system. The frequency of the continuous synchronization of the processing speeds between bale separation of the weighing system and the upstream baler is guaranteed by the control of the Rotowrap WS weighing system in exchange with the control of the channel baler.

BALE WEIGHING:

The feeding of single pressed bales to the weighing device with a substructure weighing frame takes place via conveyor belts or a push ramp. This is where the precise measurement of the bale weight takes place. Furthermore, other physical parameters such as bale length or bale volume and bale density are dynamically recorded. It is also possible to forward all recorded measurement data to a superior database system.

BALE LABELING:

The labeling station is positioned at the end of the weighing device. In the labeling station, a label on which the previously recorded data is clearly printed is applied fully automated to the weighed bale. In the labeling station, the bale is provided with a horizontal banderole (10 cm-50 cm wide) using a wrapping device. The label is then automatically affixed to this banderole. After this automatic labelling, one or more layers of the banderole can be wrapped over the label for additional protection. After the bale has been tagged, separately marked bales are reunited on the bale discharge conveyor or the inclined ramp.

Advantages:

- . Live data on all stocks of pressed bales for transparent and efficient stock management.

- Reduced workforce for general material and warehouse logistics.

- Better Traceability and accounting of storage and transport logistics of the pressed bales.

- Increase in productivity of the upstream baling press through recipe optimization via the feedback of the recorded process data.

- Visualization of all process data and evaluation options via touch screen.

- Operation of the baling press in the optimal energy performance range while avoiding operator errors when entering and adjusting discrete processing recipes.

- Full integration of Rotowrap WS weighing system with upstream baling press in the bunker management system of a sorting plant. Here, the interaction between all the machinery ensures continuous and volume-based loading of the press through the automatic recording of bale weights and filling levels and filling levels of individual collection bunkers. This leads to an optimization of the entire recycling plant.